Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

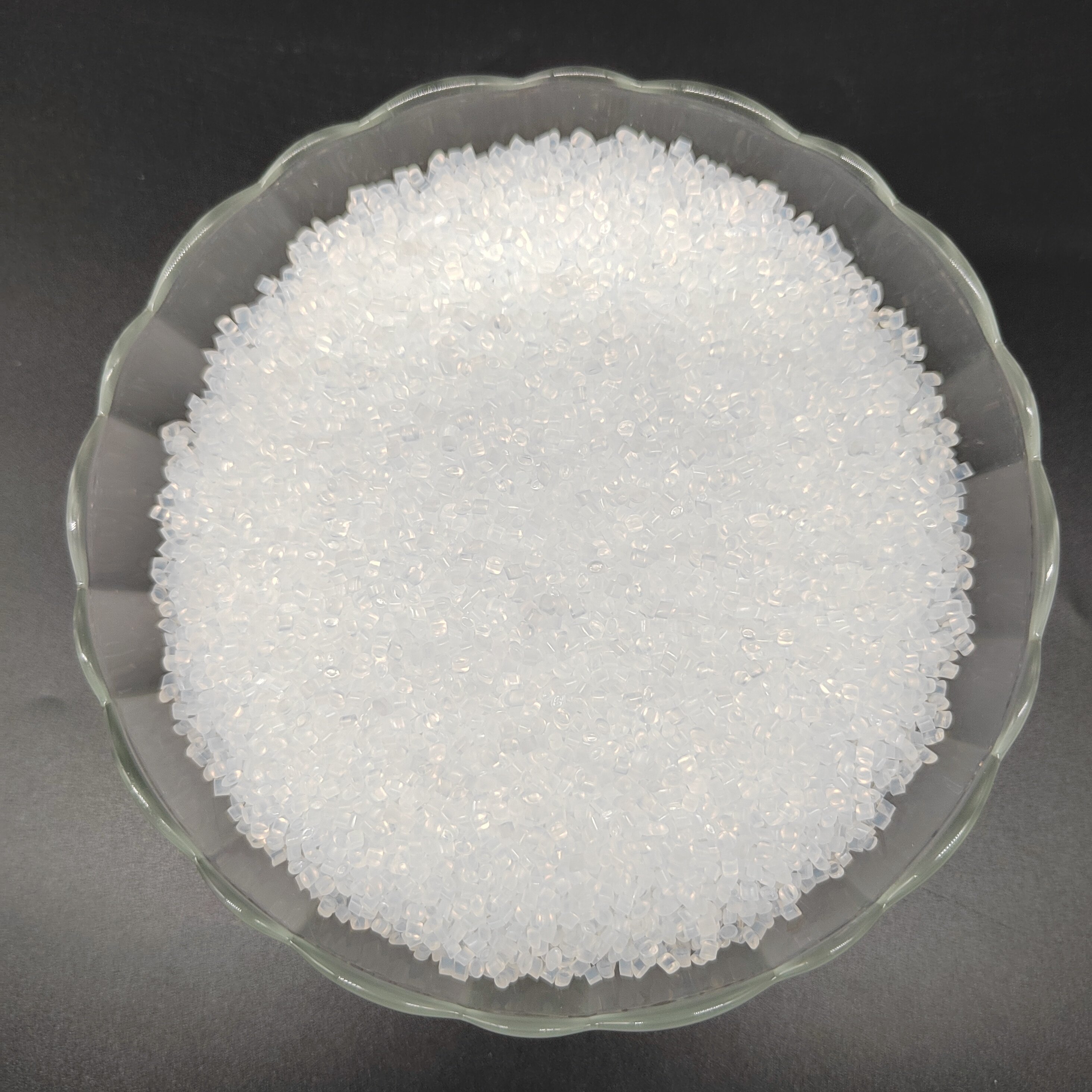

PA6 E01 FR

MI: 50 g/10min

1.5mm V0 Flame Retardant

Halogen-free

(Custom materials available according to your Technical Data Sheet)

- Информация о продукте

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

As an organic material, PA6's flammability is an obvious disadvantage. PA6 burns quickly and has a high heat release rate in the flame. In particular, a large number of combustion droplets are produced during the combustion process, which increases the risk of flame propagation.

There are two types of PA6 used in industry: reinforced and non-reinforced. However, due to the wick effect of glass fiber, reinforced PA6, especially glass fiber reinforced PA6, is more likely to burn, which limits its application in electronic appliances, transportation and other fields. The development of flame-retardant PA6 with excellent comprehensive properties is of great significance to expanding the application scope of engineering plastics and increasing their added value. Therefore, in recent years, many scientific research institutions and enterprises at home and abroad have invested a lot of manpower and material resources to reduce the flammability of PA6.

Flame retardants suitable for PA6 can be divided into halogen, phosphorus, nitrogen and inorganic compounds. Due to the different flame retardant mechanisms, flame retardant efficiency and effects on polymer material properties, reasonable selection of flame retardants is the key to preparing flame retardant PA6 with excellent performance.

Introducing our PA6 E01 FR material, which boasts not only the fundamental properties of PA6 materials but also exceptional flame retardant performance with a 1.5mm V0 rating. Notably, it is a halogen-free flame retardant material that complies with environmental standards.

Nylon 6, also known as Polyamide 6, is made from a long chain of repeating amide units linked by carbon atoms. The chemical structure of Nylon 6 consists of hexamethylenediamine (HMD) and adipic acid. These two monomers polymerize to form Nylon 6 through a condensation polymerization process, where water is released as a byproduct.

So, the basic composition of Nylon 6 includes:

- Hexamethylenediamine (HMD): C6H16N2

- Adipic acid: C6H10O4

When these two monomers undergo polymerization, they form the long chain structure of Nylon 6 with repeating units of -NH-(CH2)6-NH-CO-(CH2)4-CO-.

It seems there might be a misunderstanding here. Polyimide (PI) and Polyamide 6 (PA6) are two different types of polymers with distinct properties and applications.

Polyimide (PI): Polyimides are a type of high-performance polymer known for their exceptional thermal stability, chemical resistance, and mechanical properties. They are commonly used in applications that require high heat resistance, such as in electronics, aerospace, and automotive industries.

Polyamide 6 (PA6): Polyamide 6, also known as Nylon 6, is a type of thermoplastic polymer with good mechanical properties, excellent wear resistance, and chemical resistance. It is used in various applications like automotive parts, textiles, and industrial components.

If you are looking for information specifically on a material called "polyimide PA6," it may refer to a composite material that combines properties of both polyimide and polyamide 6. However, this specific combination may not be widely recognized or used as a standard material.

Download

-

PA6 E01 FR(1).pdf

Download PA6 E01 FR(1).pdf